Decontamination is only intended to remove or inactivate substances harmful to people and the environment from the device or installation, for safe opening and maintenance work inside the device.

Decontamination – unlike chemical cleaning - does not remove deposits/scale from the walls of the equipmnet. However, by combining steam and properly selected steam additives, in addition to deactivating harmful substances, it also degreases internal surfaces and removes residual oils.

Shortening the time of maintenance worksresults in the earlier startup of equipment or entire units, which in turn translates into a reduction of losses caused by their exclusion from the production process and earlier start means an increase in overall production, reflected in financial results.

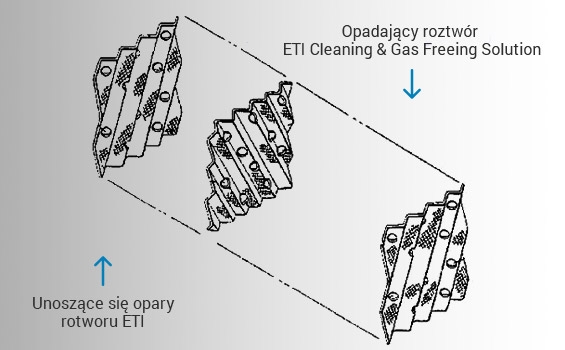

The ETI Cleaning & Gas Freeing Solution TM technology developed by EnvTech was designed to shorten the time needed to prepare individual equipment or entire units, resulting from their neutralization or decontamination before proceeding with actual maintenance or inspection works. It is usually used to remove lighter hydrocarbon fractions and in units / equipment where circulation is not possible due to technical reasons or in the absence of a effluent tank after chemical cleaning.

However, the most important feature of our technology is SAFETY. In our case, shortening the time needed for decontamination does not take place with health risk or damage to the equipment.

By using decontamination, we can easily remove: